Our Process

Australian owned.

Australian made.

Sustainable fibre packaging.

The Trusted Leader in Quality and Custom Packaging Solutions

Delivering Excellence in Packaging for Generations

Platypus Print Packaging sets the standard in the packaging industry through a commitment to cutting-edge technology, efficiency, and innovation. Our manufacturing processes are designed to deliver superior quality and reliability, positioning us as a leader in producing high-quality folding cartons.

Advanced Technology

Leveraging the world’s most advanced packaging technology

We leverage the latest advancements in printing and packaging technology to ensure our products meet the highest standards. Our facility is equipped with modern German printing presses, renowned for their precision and versatility. These presses enable us to achieve exceptional print quality and colour consistency.

In addition to our advanced printing technology, we utilise Swiss-made die-cutting and gluing equipment. This high-end machinery is known for its reliability and precision, allowing us to produce intricate and accurately finished folding cartons efficiently.

Seamless Automation

Creating seamless, automated workflows for greater efficiency

At Platypus Print Packaging, we continuously focus on automation and workflow improvements to enhance operational efficiency. By integrating automated systems and streamlining processes, we minimise manual handling, reduce errors, and accelerate production times.

This commitment to efficiency ensures that we provide a robust local solution for folding cartons, meeting the diverse needs of our customers with speed and accuracy.

Bringing Your Products to Life

Our Manufacturing Process

Our investment in state-of-the-art equipment and innovative practices reinforces our dedication to delivering packaging solutions that drive customer satisfaction and industry excellence. From design right through to warehousing and logistics, we provide you with world-class packaging solutions that elevate your brand and capture the attention of your customers.

Step 1

Design and Engineering

Our packaging design engineer produces AutoCAD key-line drawings outlining the packaging form and functionality. The product, size, weight, and storage temperature determine the engineering specifications of paper stock, paper weight, folds, perforation lines, window patches, and special varnish coatings. From here, new design concepts and innovations can be developed.

Step 2

Testing and Trials

Our packaging design engineer creates CAD-cut samples. They also produce 3D images and trial mock-ups for testing before full-scale production begins. These samples can be used for trial testing before going into major production run.

Step 3

Prepress

In prepress, we handle the preparation of art files for printing. This involves checking crucial details such as trim, bleed, image resolution, CMYK, and spot colours. Our prepress experts also manage the creation of impositions, layouts, and proofs to ensure everything meets client approval.

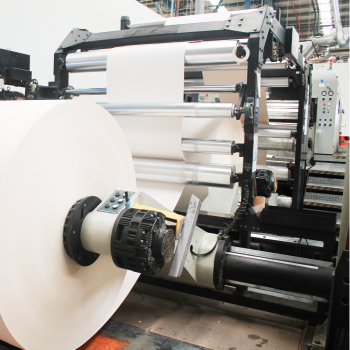

Step 4

Sheeting Department

The Sheeting Department is responsible for converting paper reels into flat sheets for printing presses. The paper is threaded through a series of rollers to remove any bends and then cut into sheets. This process can handle speeds of up to 300 metres per minute.

Step 5

Press Room

The Press Room is equipped with advanced machines and expert print specialists, operating 24/7 within a temperature-controlled, enclosed, and meticulously maintained environment. Our KBA 106 presses, featuring six-colour configurations and varnish coaters, handle up to 18,000 B1 sheets per hour. We specialise in packaging offset printing, with a strong focus on precise colour management and rigorous quality control to ensure all packaging materials meet the highest industry standards.

Step 6

Embellishing Department

Our Embellishing Department specialises in enhancing packaging with premium finishes and effects. We offer a range of services including window patching, hot foil stamping, embossing, debossing, and celloglazing. These techniques are applied to create striking visual and tactile elements that elevate the presentation and perceived value of packaging. With a focus on precision and quality, we ensure that each embellishment meets the highest standards, delivering sophisticated and impactful results for your packaging needs.

Step 7

Die-cutting Department

Our Die-cutting Department operates with precision using four Bobst 106 Diecutters, renowned for their Swiss engineering and efficiency. These machines achieve a maximum speed of 9,500 impressions per hour. Each job utilises custom-made cutting forms to ensure precise cuts and creases. Once the packaging shapes are cut and pre-creased, they are stacked flat before proceeding to the glue line for assembly and packing. This meticulous process ensures high-quality and accurate results for all your packaging requirements.

Step 8

Folder Gluer Department

The Folder Gluer Department is equipped with five advanced folder gluers, including three Swiss-made Bobst models renowned for their precision and reliability. We offer a variety of gluing options, such as straight-line, crash-lock, four-corner, and six-corner gluing, to meet diverse packaging requirements. This department transforms die-cut cartons into ready-to-fill and assemble folding cartons by folding pre-creased lines and applying glue to secure them. Once assembled, the cartons are packed into outer cartons and palletised for efficient storage and distribution.

Step 9

Warehousing Operations

Our warehousing operations include our own dedicated warehouse as well as strategically positioned facilities along the eastern seaboard of Australia. We offer a comprehensive vendor-managed inventory system to streamline inventory control and optimise supply chain efficiency. Packaging cartons are securely wrapped on pallets and stored in our warehouses. Each pallet is barcoded and integrated into our system, ensuring precise tracking and easy retrieval. This setup enables us to efficiently manage and distribute products nationwide.

Step 10

Freight Operations

Our freight operations are supported by our own fleet of vans, trucks, and semi-trailers, ensuring reliable transportation for a variety of needs. In addition to our in-house capabilities, we partner with trusted logistics providers to extend our coverage across Southeast Queensland and throughout Australia. This combined approach allows us to deliver efficient, flexible, and comprehensive freight solutions, meeting the demands of local and national distribution with precision and reliability.

Book a tour of our facility to see our manufacturing excellence firsthand.

Come along for a tour of the Platypus Print Packaging facility to see how we bring products like yours to life across all stages of our manufacturing process.