Backed by innovation. Engineered with precision.

Australian made. Australian owned. Sustainable fibre packaging.

Producing premium product packaging for local and global businesses.

At Platypus Print Packaging, we combine decades of printing heritage with cutting-edge European technology to offer functional, durable, and visually striking packaging solutions.

Whether launching a new product or seeking to elevate your brand’s presence, our packaging, backed by innovation, precision, and a tradition of craftsmanship, is manufactured to stand out in the marketplace.

State-of-the-art printing presses

Utilising the world’s most advanced printing technology.

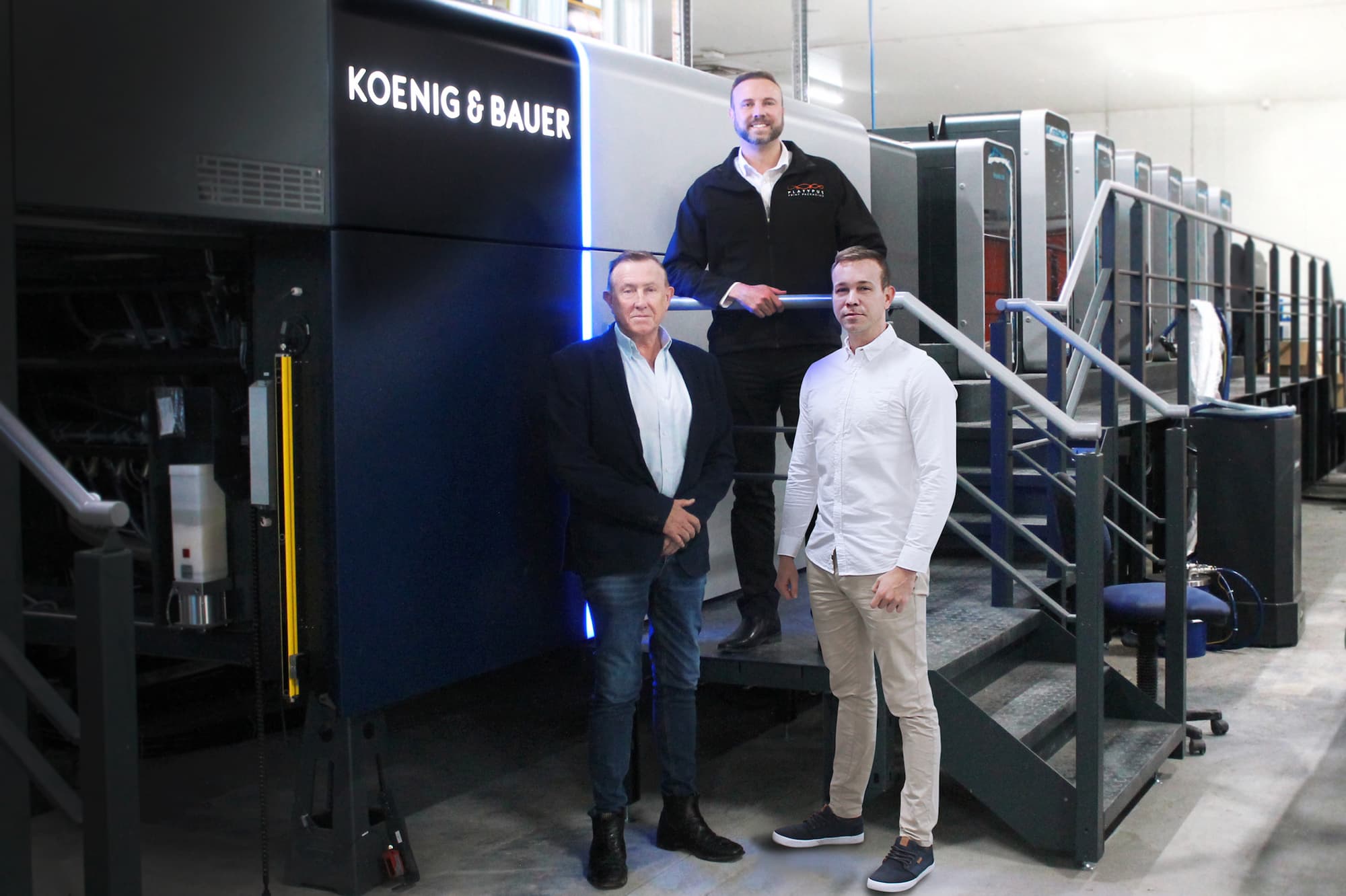

At Platypus Print Packaging, we proudly operate one of the most technologically advanced folding carton plants in Australia. We leverage state-of-the-art technology primarily sourced from esteemed European manufacturers.

Our printing capabilities are anchored by the prestigious Koenig Bauer printing presses crafted in Germany. These presses are renowned worldwide for their precision engineering and superior print quality, enabling us to produce superior packaging that meets the highest colour fidelity and detail standards.

Our printing presses operate 24/7 in a concealed, temperature-controlled environment and have the capacity to produce up to 18,000 B1 sheets per hour with minimal downtime.

Die-cutters and gluers

Leveraging the most efficient and innovative die-cutters and gluers.

Complementing our printing prowess are the Bobst die-cutters and folder gluers, meticulously crafted in Switzerland. These machines are synonymous with innovation and efficiency in the packaging industry, allowing us to execute intricate die-cut shapes and assemble folding cartons with unmatched accuracy and speed.

Our die-cutting machines run at a maximum speed of 9,500 impressions per hour or 76,000 cartons per hour when planned 8 up

In-house production

Developing unique product packaging with superior in-house production capabilities.

In addition to our world-class technology, Platypus Print Packaging has extraordinary comprehensive in-house production capabilities. From sheeting to cello glazing, embossing, debossing, hot foil stamping, leaflet insertion, litho-lamination, and window patching, every manufacturing stage is meticulously managed within our facility.

This integrated approach not only ensures seamless workflow but also provides rigorous quality control throughout the production process.

Book a tour to see our manufacturing precision firsthand.

Want to see firsthand how our advanced technology and skilled team bring packaging concepts to life? Then, come along for a tour of the Platypus Print Packaging facility! This transparency underscores our commitment to excellence and customer satisfaction, demonstrating our capability to deliver packaging solutions that exceed expectations.